عندما يذكر الناس أكياس EVA، فإنهم يفكرون دائمًا في كيس التغليف البلاستيكي المصنوع من EVA.

ولكن اليوم سوف نقدم لكم منتجًا مبتكرًا:

أكياس صمام EVA

.

ما هي أكياس قيمة EVA؟

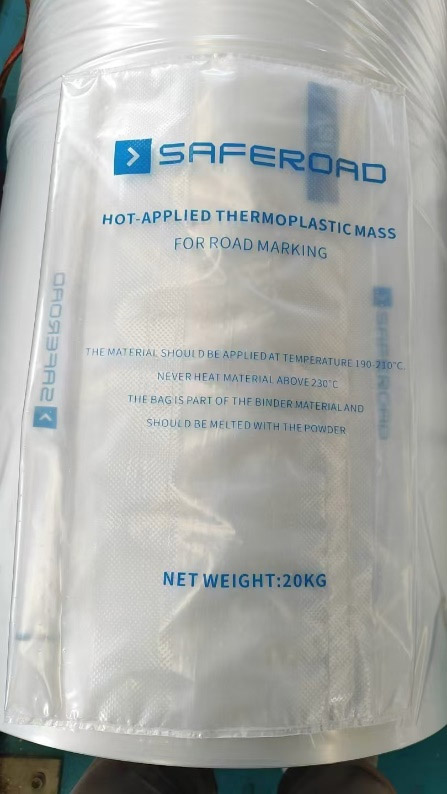

أكياس الصمامات ثنائية الطبقة المصنوعة من مادة EVA (أسيتات إيثيلين فينيل) ليست مواد تغليف، بل هي مادة مضافة تشبه الغشاء تُستخدم في طلاءات الذوبان الساخن لعلامات الطرق.

لماذا تختار حقائب القيمة EVA؟

بعد خلط وإذابة 2.5 كجم من أكياس صمام EVA مع 1 طن من طلاء الذوبان الساخن، سيتم ممارسة تأثيرات كبيرة على قوة الضغط، وقوة التصاق خرز الزجاج، ومقاومة التشقق، ومقاومة الطقس لطلاء العلامة.

معلمات حقيبة صمام EVA:

| أسماء أخرى | كتلة بلاستيكية حرارية مطبقة ساخنة |

| صفات | أكياس قيمة من مادة EVA ذات طبقتين |

| مادة | إيفا + بولي إيثيلين |

| طول | 610±10 مم |

| عرض | 350±10 مم |

| نقطة الانصهار | 100±5 درجة مئوية |

| سمك الطبقة الواحدة | 6.0 ثانية ± 0.5 ثانية |

| وزن | 63±5 جرام |

وفيما يلي تحليل مفصل لكل بند على حدة:

1. التأثير على قوة الضغط (في ظروف 60 درجة مئوية)

متطلبات JT/T280-2022: يجب أن تكون قوة الضغط عند 60 درجة مئوية ≥2 ميجا باسكال.

في الطلاءات المصهورة بالحرارة ذات مقاومة الضغط العالية، تكون خطوط العلامات المتكونة عرضة للتشقق. بعد إضافة أكياس التغليف المرنة، ستتحسن مقاومة الطلاء للتشقق بشكل كبير.

- تأثير تليين أكياس الفيلم المرن EVA: مع نقطة انصهار منخفضة ومرونة معينة حتى عند -20 درجة مئوية، فإنها ستقلل من الصلابة الكلية لطلاء الذوبان الساخن.

- انخفاض في قوة الضغط: تتمتع الطلاءات الساخنة التقليدية (راتنج البترول + الحشو) بصلابة عالية (≥ 2 ميجا باسكال) عند 60 درجة مئوية، ولكن بعد إضافة 40 كيس صمام مزدوج الطبقة، يتم تعزيز مرونة طلاء العلامة.

2. التأثير على التصاق الخرز الزجاجي

- تعزيز التصاق أكياس صمام EVA:

- تحسين قابلية البلل المنصهر: بعد الذوبان، يتمتع الفيلم المرن بسيولة جيدة، مما يمكنه لف حبات الزجاج بشكل أفضل وتحسين قوة الترابط.

- التخزين المؤقت المرن لتقليل التساقط: إن الاستطالة العالية عند كسر أكياس الفيلم المرنة تمكنها من الخضوع للتشوه المرن تحت أحمال المرور، مما يقلل من خطر تساقط حبات الزجاج بسبب الصدمات.

- التأثيرات العملية:

- يتم زيادة معدل التصاق حبات الزجاج، وتعزيز مقاومتها للصدمات، مما يؤخر تخفيف معامل السطوع الانعكاسي لخطوط التحديد.

- تم تحسين المتانة على المدى الطويل، مع معدل احتفاظ أعلى لخرزات الزجاج تحت الأحمال الديناميكية، مما يؤدي إلى إطالة عمر الانعكاس لخطوط التحديد.

3. التأثير على مقاومة التشقق

- تأثير تقوية أكياس الفيلم المرنة:

- قدرة تشتيت الإجهاد المحسنة: يسمح الاستطالة العالية لأكياس الفيلم المرنة ذات الطبقتين لها بامتصاص الإجهاد الناجم عن انكماش سطح الطريق أو اهتزاز المرور، مما يقلل من انتشار الشقوق.

- تحسين مقاومة التشقق في درجات الحرارة المنخفضة: أقل من -20 درجة مئوية، لا تزال أكياس الفيلم المرنة ذات الطبقتين تحافظ على المرونة، مما يقلل من خطر التشقق الناتج عن هشاشة درجات الحرارة المنخفضة.

- التأثيرات العملية:

- انخفاض معدل تشقق خطوط وسم الذوبان الساخن القياسية الجديدة. مقارنةً بنظام راتنج البترول النقي، يمكن تقليل احتمالية التشقق بنسبة 30%-50%.

- يتم تقليل عدد الشقوق الدقيقة، ويصبح سطح خطوط التحديد أكثر سلاسة، ويتم تقليل مشكلة التقشير الناتجة عن الشقوق.

4. التأثير على مقاومة الطلاء للعوامل الجوية

- خصائص مقاومة الطقس لأكياس الفيلم المرنة ذات الطبقتين:

- مقاومة الأشعة فوق البنفسجية: المواد الخام لأكياس الفيلم المرن ذات الطبقتين مصنوعة من EVA + المعدلات، والتي يمكنها أن تقلل بشكل فعال من اصفرار وتفتت طلاء العلامة تحت الأشعة فوق البنفسجية طويلة المدى.

- مقاومة الرطوبة والحرارة: تتميز أكياس الفيلم المرنة ذات الطبقتين بمعدل امتصاص منخفض للغاية للرطوبة ولا تؤثر على المتانة طويلة الأمد في البيئات ذات درجات الحرارة العالية والرطوبة العالية.

5. ملخص التأثيرات الشاملة

إن إضافة أكياس التغليف المصنوعة من مادة EVA (40 كيسًا، أي ما يعادل 2.5 كجم تقريبًا من الغراء المرن المضاف إلى طن واحد من الطلاء) يمكن أن يقلل من هشاشة خطوط العلامات الساخنة ويحسن بشكل كبير من التصاق حبات الزجاج ومقاومة التشقق والصلابة في درجات الحرارة المنخفضة ومقاومة الطقس.

يمكن أن تصبح الأكياس المرنة ذات الفم الصمامي المصنوعة من مادة EVA ذات الطبقة المزدوجة من الدرجة السينمائية حلاً اقتصاديًا وفعالًا لتحسين الأداء الشامل لخطوط وضع العلامات بالذوبان الساخن.